Improving Spring Performance: Stress Relieving and Its Parameters for Different Spring Materials

Introduction

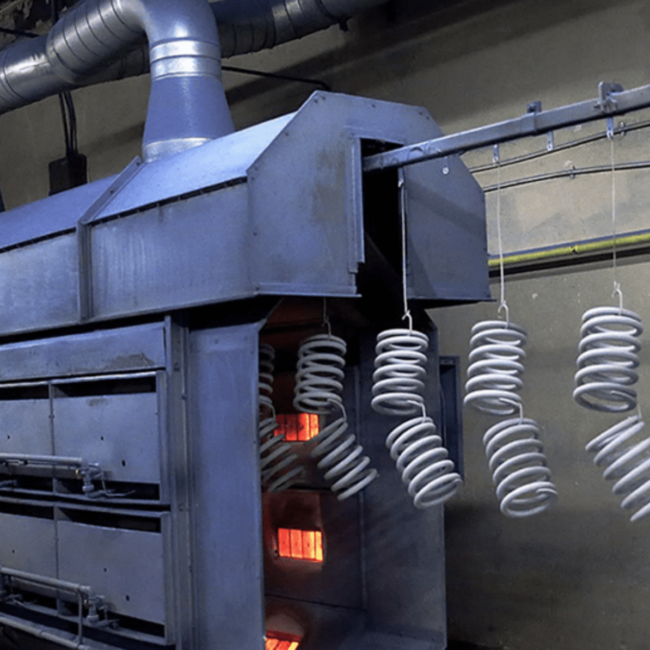

Springs are essential in many industries, but to work well, they need to be stress relieved. Stress relieving is a heat treatment process that gets rid of internal stresses in springs, making them stronger and last longer. Let’s dig into the details of stress relieving for springs and understand how it varies for different types of spring materials.

Understanding Stress Relieving

Stress relieving is like a spa day for springs. It’s a controlled heating and cooling process that helps springs chill out. This process has a few main benefits:

Relaxes Built-Up Stress: During manufacturing, springs can get stressed out. Stress relieving helps them relax and be less likely to deform or fail under pressure.

Makes Springs Bendy: Stress relieving makes springs more flexible, so they can handle stress without breaking.

Lasts Longer: It also increases how many times a spring can be used before wearing out.

Stress Relieving Parameters for Springs

Not all springs are created equal, and the way we help them relax (stress relieve) depends on the material they’re made of. Here’s what we need to consider:

Temperature: The heat level for stress relieving depends on the spring’s material. Most steel springs are heated to around 350°C to 650°C (660°F to 1200°F). Springs made from nickel alloys may need even hotter temps, while copper alloy springs like it a bit cooler.

Time: Springs need a bit of spa time. The duration of stress relieving can be a few hours, with thicker springs needing more time to ensure they chill out completely.

Cooling Down: After the heat treatment, springs need to cool down. This can be done with regular air cooling or cooling in a furnace. The choice depends on what the spring is made of and the desired properties.

Where It Happens: The environment is important, too. We usually try to do stress relieving in a neutral atmosphere to prevent rust or damage to the spring’s surface.

Material-Specific parameters:

Steel Springs: These springs get heated to around 550°C (1020°F) for a few hours, and then they cool down in a furnace. This helps get rid of stress and keeps the spring’s strength.

Stainless Steel Springs: Stress relieving for stainless steel springs is performed at temperatures similar to those for standard steel springs. This treatment ensures stress relief while preserving the spring’s corrosion-resistant properties.

Nickel Springs: For springs made of nickel alloys like Inconel, we need to heat them up even more, often between 800°C to 1100°C (1470°F to 2010°F), and then cool them down in a controlled way.

Copper Springs: Springs from copper alloys, like phosphor bronze, get heated at lower temperatures compared to steel or nickel, usually around 250°C to 350°C (480°F to 660°F).

Conclusion

Stress relieving is like a spa day for springs, making them stronger and more durable. Knowing how to do it right, depending on the material, helps us create springs that work well and last longer in all kinds of industries. By tailoring the stress relieving process to the specific material used, manufacturers can create springs that offer superior performance, durability, and reliability, meeting the stringent requirements of diverse industries. So, when you see a spring in action, remember that it probably had a good stress-relieving session to thank for its reliability and longevity!